Gum and varnish residues in fuel lines are the most common cause of poor engine function. Sea Foam Motor Treatment works to stabilize stored fuel up to 2 years. Adding Sea Foam to stored tanks helps fuel resist evaporation, preserves ignition vapors, adds protective lubricity, and prevents the formation of gum and varnish in fuel systems.

Testing Results

To test fuel stabilization capabilities, fuel tanks were filled with diesel and gasoline fuel and treated with several fuel additives, including Sea Foam Motor Treatment, for 24 months. Over the course of two years, the flashpoint, evaporation levels, and change in fuel color were monitored.

Sea Foam Motor Treatment showed positive results in every category. Sea Foam is ranked excellent in performance and can be trusted for use as an effective stabilization product.

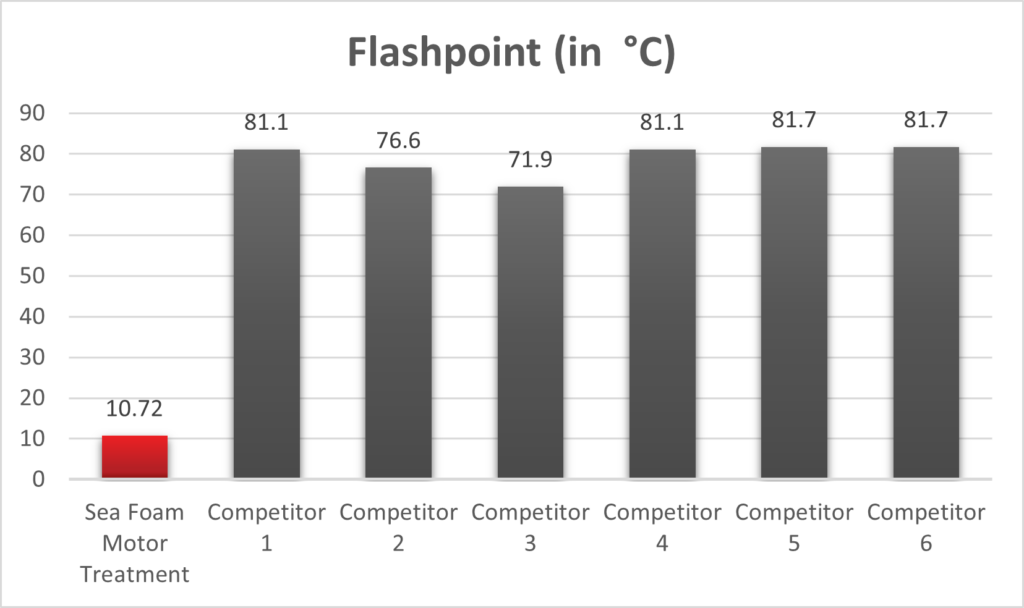

Flashpoint

The flashpoint of an individual additive is a good indicator of how it will affect the fuel mixture. The lower the flashpoint of fuel, the easier it is for the fuel to ignite. The flashpoint of Sea Foam and six other fuel stabilizing additives were measured. A heated evaporation test was completed by heating Sea Foam Motor Treatment and other fuel stabilizing products and then testing the resultant.

Sea Foam Motor Treatment had the lowest flashpoint of all additives tested. Mixing Sea Foam with fuel may help to stabilize it at a lower overall flashpoint. Fuel mixture samples treated with Sea Foam Motor Treatment remained stable much longer than other products tested.

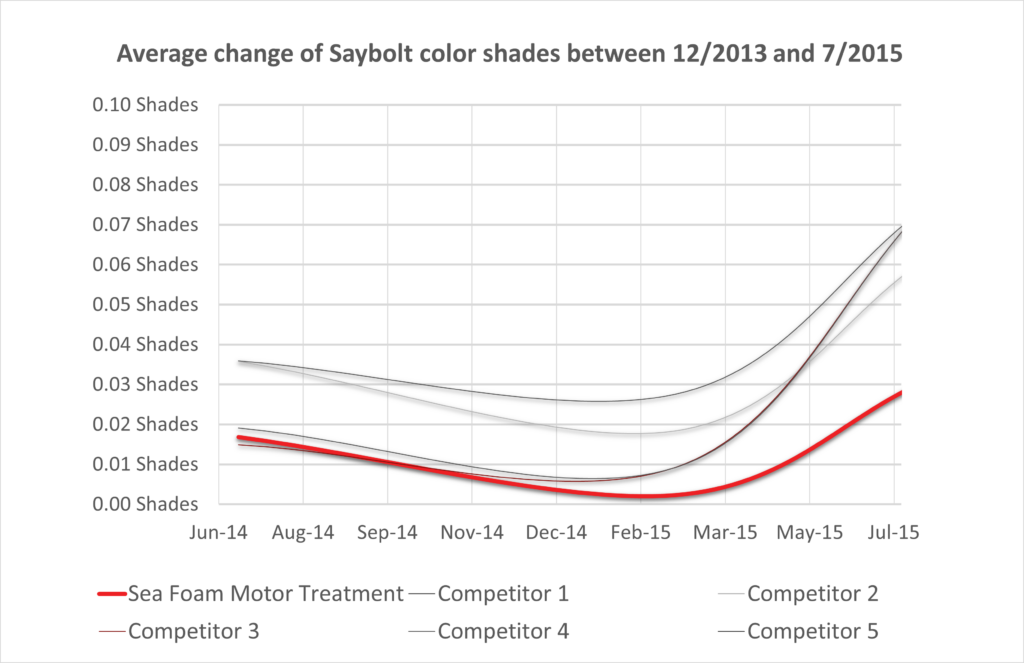

Color Change

Color change can indicate oxidation or degradation of fuel. A treated fuel that shows little-to-no color change over time is

an indication that little oxidation or degradation of the fuel is taking place. One of the standards used for petroleum products to determine color measurement is the Saybolt color chart. This matching of color can help to indicate the type and quality of fuel.

Straight, non-ethanol gasoline was dosed with five different fuel additives, including Sea Foam Motor Treatment. Each sample was viewed and recorded with the same light settings, same person, and same camera. The assignment of Saybolt color was done live and not by using photographs.

Sea Foam exhibited the lowest amount of color change over the twenty-four month testing period between color chart readings. This indicates that little oxidation or degradation of the Sea Foam-treated fuel had taken place.

Evaporation

A good fuel stabilizer will reduce evaporation in fuel. Multiple samples of treated fuel were added to beakers and observed over 24 months.

The testing indicated that Sea Foam Motor Treatment stabilizes fuel better than other additives based upon the level of evaporation in non-ethanol fuels with no two-cycle oil added. Sea Foam stablizes fuel as well or better than other additives based upon the level of evaporation in ethanol fuels with and without two-cycle oil added. The diesel fuel beakers showed little or no evaporation over the first twenty-four months of the test.

Conclusion

Sea Foam Motor Treatment showed positive results in every category and can be trusted to be used as an effective stabilization product.

- Sea Foam Motor Treatment shows very little color change while other products darken.

- Sea Foam Motor Treatment showed very favorable Flash Point results and tested superior with certain fuel mixtures.

- The product shows favorable evaporation rates in fuel.